Quality of processed potato product depends on the quality of the raw material. The quality of raw material is judged by two factors viz. morphological characters as well as biochemical composition of the variety. Among the morphological characters shape and size of the potatoes is of utmost importance. For preparation of chips round to round-oval potatoes are preferred, whereas, for preparation of French fries, long oval potatoes are preferred. Potatoes should meet some basic requirement for preparing chips and French fries since the quality of product is determined by its appearance (i.e colour), crispiness and taste. Light or light golden yellow colour is desirable, whereas brown or black colour is undesirable in chips and French fries. Potatoes of 40-60mm diameter and above are suitable for preparation of chips and French fries. Small sized potatoes are used for canning. Moreover to avoid losses during peeling and to maintain the shape of the slices, potatoes with shallow eyes are preferred for processing into chips and French fries.

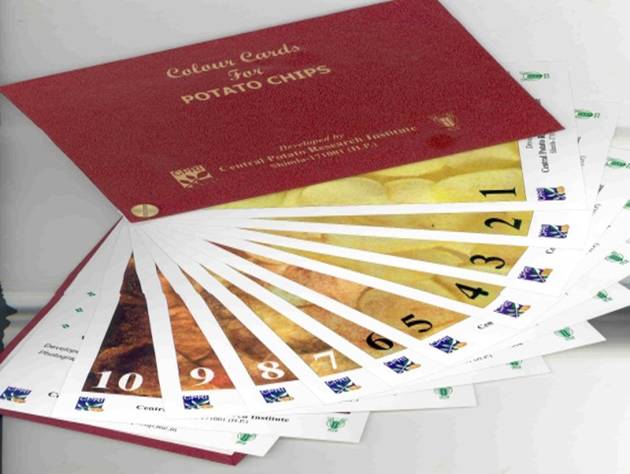

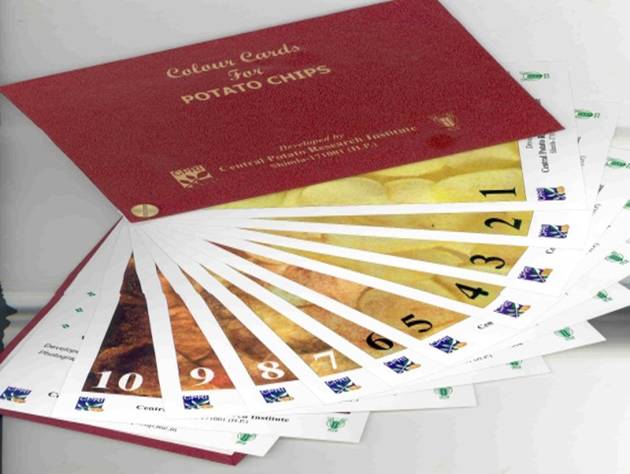

Among the biochemical attributes, dry matter and reducing sugars are considered as of utmost importance. Potatoes contain about 80% water and 20% dry matter. Potatoes with high dry matter are preferred for fried and dehydrated products and with low dry matter are used for canning. The dry matter content of potato determines the yield of the products and the quantity of oil absorbed during frying. High dry matter leads to higher yield of products with lower oil content. The acceptability of fried potato product depends on the level of the reducing sugars (glucose and fructose) present in the raw material. Potatoes contain appreciable amount of sucrose, glucose and fructose. For preparing good quality potato chips, the reducing sugars content should be less than 150 mg/100g tuber fresh weight. If the level of reducing sugars is more than this, the fried product becomes dark in colour and unacceptable. The dark colour is formed due to a reaction called Maillard reaction between reducing sugars and amino acids. Maillard reaction takes place during the high temperatures of frying. For ranking of colour in potato chips, colour cards have been developed by Central Potato Research Institute (CPRI), Shimla. These colour cards have scores of 1-10, higher the colour score more is the browning. A colour score up to 4 is acceptable while 5 and above is unacceptable.

Colour cards for potato chips

The maillard reaction which produces dark colouration in potato products is also responsible for production of another un-advantageous trait 'Acrylamide' as a by product of the reaction between amino acid asparagines and reducing sugars. Since acrylamide has been categorized as a carcinogen, there is high concern for its concerntration in the processed potato products. All the Indian varieties have been profiled for the formation of acrylamide in the chips and French fries and the results have clearly shown that the varieties known for good processing quality having low reducing sugars also produce less acrylamide in the products and hence, it is recommended that for processing of potatoes, only processing varieties may be utilized.